Dams are huge constructions that are constructed to contain water, generate power, and manage floods. Modern engineering employs geotextile and geomembrane in order to make dams durable, stable, and waterproof. These are sophisticated geosynthetics that enhance the safety of the dams and make them last longer.

The use of Geomembranes in Dams

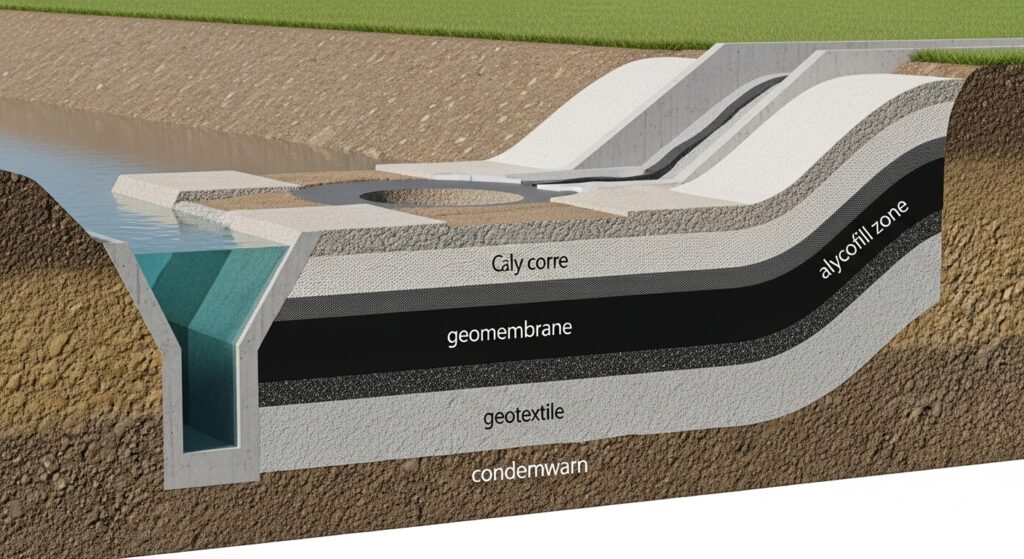

The waterproof liner is a geomembrane (typically of HDPE (High-Density Polyethylene)) that is placed in the inside of the dam structure or on the upslope slope (the one facing water).

Its primary task is to prevent leakage.

Where Geomembranes Are Used

- Top of dams made of earth-fill.

- Core trench lining

- Reservoir floor lining

- Spaces of contact between dam and foundation.

Advantages of Geomembrane in Dams

- 100% waterproof barrier

- Eliminates water leakage within and under the dam.

- Prevents wear and tear of foundation.

- Strengthens the safety and life of the dams.

- Performs in high or low temperatures.

- Less expensive in terms of maintenance as compared to traditional clay cores.

The HDPE geomembranes are also applied particularly in the repairing of old dams in which seepage has become a significant problem.

The application of Geotextile in Dam Projects

Geotextile is a durable, permeable cloth which is installed in the space between soil layers, rocks or geomembrane. It is done to safeguard, filter and fortify the dam structure.

Where Geotextile Is Used

- And covered with the geomembrane.

- Rear riprap on the dam face.

- In drainage layers

- Circa filters in the vicinity of the foundation.

Geotextile is advantageous in Dams

- Prevents soil erosion

- Functions as a filter where water can pass through but the soil will be prevented.

- Offers roll protection to geomembranes.

- Enhances drainage and decongests the dam.

- Strengthens weak soil areas

The geotextiles are used to resist the pressure of the heavy waters and minimize the chances of structural damage in dams.

The interaction of Geotextile and Geomembrane

These two materials are combined together in most dam projects:

- Protection/ Filtration Geotextile layer.

- HDPE geomembrane (proofing).

- Top cover or rock layer is geotextile.

This powerful, state-of-the-art mechanism will guarantee the dam will be stable, leak-free, and safe many decades.

Conclusion

Geotextiles and geomembranes play a vital role in modern dam engineering and water resource management. Geomembranes serve as an effective impermeable barrier, controlling seepage and protecting the dam body and foundation from water intrusion. Geotextiles work alongside them by offering filtration, cushioning, separation, and reinforcement, ensuring long-term structural stability.

When combined, these geosynthetic solutions improve dam safety, enhance durability, and increase operational efficiency. They contribute to secure water storage systems that support irrigation, flood control, and community water supply needs.

NM GEO SYNTHETIC delivers high-quality geotextiles and geomembranes engineered to meet the demanding requirements of dam construction and rehabilitation projects worldwide. Our products provide dependable performance for sustainable and resilient water infrastructure.