In today’s rapidly advancing construction and infrastructure industry, ensuring long-term soil stability, effective drainage, and structural durability is essential. Geotextile fabric has emerged as a dependable geosynthetic material that supports these needs by improving ground performance while reducing construction costs and environmental impact.

Geotextile fabric is widely used in civil engineering, road construction, environmental protection, and agricultural projects due to its strength, permeability, and versatility. It plays a critical role in enhancing the lifespan and performance of infrastructure projects across varying soil and climatic conditions.

What Is Geotextile Fabric?

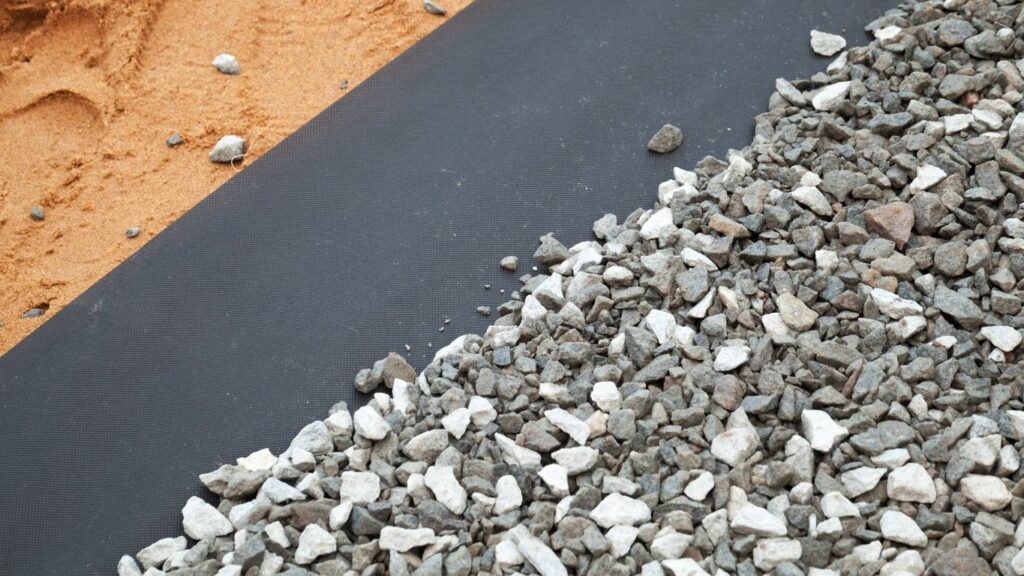

Geotextile fabric is a permeable, engineered textile manufactured from synthetic fibers such as polypropylene or polyester. It is designed to interact with soil and aggregates to perform essential functions including separation, filtration, drainage, reinforcement, and protection.

By acting as a stable interface between soil layers, Geotextile fabric improves load distribution and minimizes soil movement, making it a key component in modern geotechnical solutions. High-quality Geotextile products suitable for a wide range of applications are available through https://nmgeosynthetic.com/.

Key Functions of Geotextile Fabric

Separation

Prevents the mixing of different soil layers, especially between subgrade soil and aggregate layers in road and pavement construction.

Filtration

Allows water to pass through while retaining soil particles, ensuring efficient drainage without soil loss.

Drainage

Facilitates controlled water flow within soil structures, reducing hydrostatic pressure and water accumulation.

Reinforcement

Improves the tensile strength and load-bearing capacity of soil, enhancing structural stability.

Protection

Shields geomembranes and soil surfaces from mechanical damage and erosion.

Types of Geotextile Fabric

Woven Geotextile

Woven Geotextile fabrics are produced by weaving individual fibers together, offering high tensile strength and low elongation. These are commonly used in heavy-duty applications such as highways, embankments, and load-bearing foundations.

Non-Woven Geotextile

Non-woven Geotextile fabrics are manufactured using needle-punched or heat-bonded fibers. They provide excellent filtration and drainage properties and are widely used in erosion control, drainage systems, and landscaping projects.

Applications of Geotextile Fabric

Geotextile fabric is used across multiple industries due to its adaptability and performance benefits:

- Road and highway construction

- Railway track stabilization

- Drainage and filtration systems

- Erosion control on slopes and embankments

- Landfills and waste containment projects

- Irrigation canals and water management systems

- Landscaping and agricultural soil stabilization

These applications help extend the service life of structures while reducing maintenance requirements.

Benefits of Using Geotextile Fabric

- Enhances soil strength and stability

- Improves drainage efficiency

- Reduces construction and maintenance costs

- Extends the life of infrastructure projects

- Environmentally friendly and sustainable

- Easy to install and adaptable to various site conditions

Choosing the Right Geotextile Fabric

Selecting the appropriate Geotextile fabric depends on factors such as soil type, load requirements, water flow conditions, and project objectives. Using the correct specification ensures optimal performance and long-term durability. Expert guidance and a wide range of Geotextile solutions can be found at https://nmgeosynthetic.com/ to meet diverse project requirements.

Geotextile Fabric as a Smart and Cost-Effective Engineering Solution

Geotextile fabric has become an essential material in modern construction and environmental engineering. Its ability to improve soil performance, manage water flow, and protect structural layers makes it a smart and cost-effective solution for a wide range of applications. When properly selected and installed, Geotextile fabric significantly enhances project reliability and sustainability.